Ritchie Technology

From paddock to product: recycling farm plastics

Partnership at a glance

- Dr William Ritchie, founder of Ritchie Technology (Rtec), developed a compact recycling machine to process agricultural plastic waste on-site

- Rtec partnered with La Trobe University to access materials science expertise and research capabilities

- The project received $145,000 in funding from Sustainability Victoria’s Circular Economy Markets Fund

- With support from La Trobe's Accelerator Program and TILT i5.0+, Rtec refined its product and business strategy

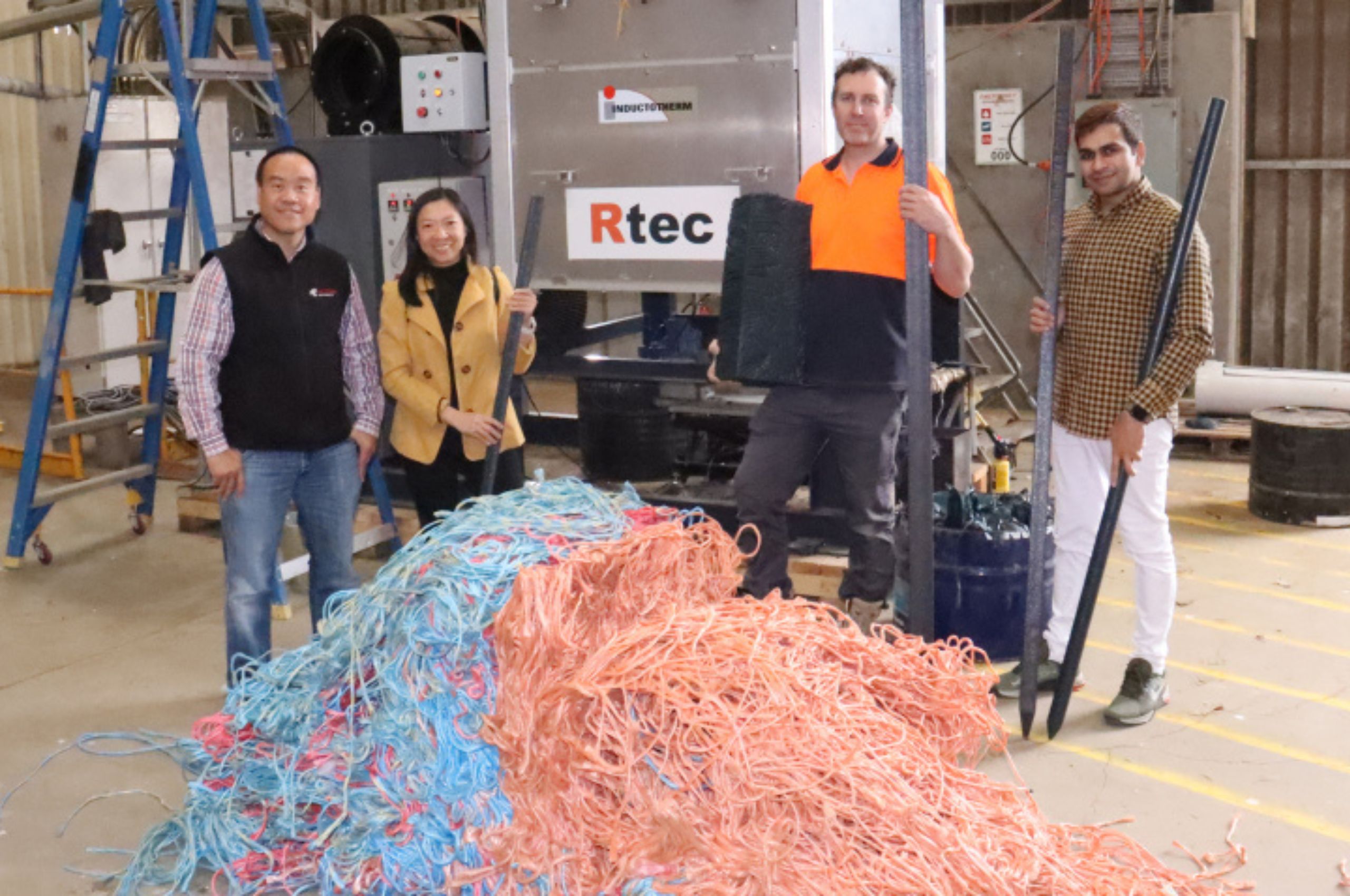

- The collaboration enabled lab-based testing, prototyping, and validation of recycled plastic products – including garden beds, fencing posts, and a park bench

Case study

The idea started with a simple question: could agricultural plastic waste – like baling twine and fertiliser bags – be recycled in a more efficient, accessible way?

Dr William Ritchie, a molecular scientist working as an R&D consultant at the time, was approached to take a look by his uncle, Michael Ritchie, who works in recycling and waste management. With experience recovering plastic from farms, his uncle saw a clear opportunity for improvement. Traditional mechanical recycling – with its reliance on washing, shredding, and pelletising – seemed ripe for disruption.

Dr Ritchie began developing a compact, scalable plastic recycling machine that could process dirty, mixed plastics directly on-site. But turning that early idea into a functioning product and viable business required support, so he reached out to La Trobe University, where he had completed both his undergraduate degree and a PhD in molecular biology.

“I know the capabilities La Trobe have,” he says. “I just asked them for help saying, ‘We have a potential research and development opportunity here. We need to turn it into a business’.”

From brainwave to business plan

In 2019, Dr Ritchie joined the La Trobe Accelerator Program, designed to help early stage startups grow. “The Accelerator Program was highly beneficial for where we were at that stage,” he says.

As Ritchie Technology (Rtec) developed, he stepped into TILT i5.0+ – a peer-to-peer innovation and leadership program delivered by La Trobe in partnership with the Australian National University and Fraunhofer Institute for Experimental Software Engineering, and funded by the Australian Government’s Strategic University Reform Fund (SURF).

“They said it was a more advanced accelerator – and they weren’t wrong,” Dr Ritchie says. “It helped me step back and break the business down into simple elements, then reconstruct it with a clearer path forward.”

Being surrounded by other regional business leaders added extra value. “I got access to people who had already done a lot of what I need to do,” he says. “Their insights and perspectives were hugely helpful. It was a great little group.”

Putting plastics to the test

During the TILT program, Dr Ritchie was introduced to Associate Professor Ing Kong, a materials engineering researcher at La Trobe’s Bendigo campus.

“At the time, not many people at the university were working on plastic recycling,” Prof Kong says. “It’s definitely my background, but I was probably the only one back then.”

Prof Kong saw potential in Dr Ritchie’s concept. “They were focused on the agricultural sector – mainly single-use plastics, often one type at a time. That actually makes recycling more straightforward,” she says.

Their collaboration began with testing plastic samples. This work attracted a $145,000 grant from Sustainability Victoria’s Circular Economy Markets Fund, enabling lab analysis and small-scale product development.

“They had the machine but not the equipment to test or verify the incoming plastic waste,” Prof Kong explains. “That’s where La Trobe came in. We analysed the types of plastic, assessed contamination or degradation, and identified suitable processing temperatures.”

The results were encouraging. In one trial, Prof Kong’s team compared baling twine before and after processing through the Rtec machine. “We found the recycled material retained very similar strength and thermal properties.”

Her team assembled a park bench from the moulded recycled plastic, which is now installed on campus. Using La Trobe’s UV weathering accelerator, they simulated years of outdoor exposure to ensure the materials retained their strength and durability.

Turning waste into wins

The collaboration has paid off for both sides.

“La Trobe has capability we don’t – to analyse, validate, and test,” Dr Ritchie says. “It brings scientific rigour and academic credibility to everything we’re doing.”

The partnership also helped shape the company’s internal strategy. “Now that we’re bringing in new people, I have a much clearer idea of what skills we need and who we’re looking for,” he says.

For Prof Kong, the project has opened new doors. “This was probably one of the first projects here focused on recycling material,” she says. “It’s helped raise La Trobe’s profile and shown what our researchers and facilities are capable of.”

The partnership has also helped connect La Trobe with the local community. Prof Kong now uses the project in outreach activities, demonstrating how everyday items like yoghurt tubs and ice-cream containers can be transformed into practical, long-lasting products.

They have a capability we don’t – to analyse, validate, and test. It brings scientific rigour and market credibility to everything we’re doing.

Closing the loop

While Prof Kong continues to receive plastic samples from Dr Ritchie for testing, the next big challenge is securing further funding – but both partners are optimistic.

“We’d love to bring on an industry-based PhD to support product development,” says Prof Kong. “And we’re working on a database that catalogues plastic types and properties, so future users can refer to it when using Rtec’s technology.”

For Dr Ritchie, the focus is now on commercialisation. “The machine is quite established. The next step is creating new products, improving material properties, and getting it to market.”

And while the initial focus has been agricultural waste, there’s room to expand. “We’re trying to extend into the medical sector,” Prof Kong says. “It’s a huge waste stream that most recyclers avoid – but this technology can handle it.”

To connect about university partnership opportunities, contact La Trobe Industry at industry.engagement@latrobe.edu.au

For more information about La Trobe Entrepreneurship programs, including the LaunchPad Pre-Accelerator, visit Innovation and Entrepreneurship.