Department of Engineering facilities

The Department of Engineering has world class facilities in manufacturing, civil and electronics engineering, located at La Trobe’s Melbourne and Bendigo campuses.

Our facilities provide students with interactive, industry-focused learning experiences where they can hone their technical and problem solving skills. They also serve as ideal collaborative spaces, where our researchers work with industry to produce innovative engineering solutions that benefit us all.

Manufacturing engineering

These laboratories allow our researchers to develop new methods and processes in manufacturing, create new materials, and assist in the development of improved and sustainable methods of extracting and using raw materials from our environment.

This laboratory facilitates new materials development, advanced manufacturing methods and materials characterisation. There is a materials processing space and equipment for the development of new ceramic, polymer and metallic materials, as well as metallographic and surface characterisation.

Equipment includes cutting and polishing equipment, contact angle measurements, and optical microscopy. The manufacturing space includes welding and furnace facilities as well as a state-of-the-art dynamic/static universal testing machine.

This laboratory is equipped with wet and polishing facilities for the microstructural and chemical analysis of new materials. Polymeric, metallic and ceramic parts can be cut, polished and etched to reveal their internal structure, which can then be analysed using advanced instruments such as a scanning electron microscope or Nomarski optical microscope. The laboratory is capable of preparing solid, liquid and gaseous samples for a wide range of further analyses.

Key equipment in the laboratory includes analytical balances, a centrifuge, hot plates, pH meters with standard buffers, a conductivity meter, polishing machines, ovens, sputter coater, pellet press, hydraulic presses, micro-hardness indentation and optical microscopes, facilitating comprehensive material characterisation and sample preparation for a range of research applications.

This laboratory is supported by a state-of-the-art polymer research facility dedicated to developing advanced functional polymer and composite materials, including thermosets, thermoplastics and rubber. The laboratory conducts both fundamental scientific research and industry-focused innovation, specialising in the design, synthesis, processing and performance analysis of cutting-edge materials. Current research areas include functional polymer nanocomposites, natural fiber composites, biocomposites, 3D printing of polymers and composites, 3D bioprinting of tissues and sustainable polymer composites.

The facility is equipped with advanced tools for composite processing, such as injection molding, filament extrusion, compression molding, internal mixing, electrospinning and 3D bioprinting. Characterisation equipment includes thermogravimetric analysis, dynamic mechanical analysis, differential scanning calorimetry, UV weathering accelerators, FTIR spectroscopy, enabling comprehensive material development and analysis.

This laboratory is equipped with advanced additive and subtractive manufacturing technologies for rapid prototyping of specialised research apparatus. It enables users to machine and assemble simple parts as well as complex assemblies using a wide range of materials. The laboratory also serves as a training ground for students to learn computer-aided machining practices in a supervised environment, where they design and develop test samples for analysis.

Key equipment in the laboratory includes a 5-axis CNC milling machine, 3-axis CNC milling machine, abrasive waterjet cutter, laser cutter, injection molder, and fused deposition modeling and stereolithography 3D printers, supporting a wide range of manufacturing and prototyping applications.

Civil engineering

Our civil engineering laboratories operate at La Trobe’s Bundoora and Bendigo campuses. We have laboratories for structures, geotechnical and hydraulics engineering, which house a wide range of equipment for testing and numerical analysis. These facilities are available for teaching, research and engagement with industry.

This state-of-the-art facility that enables students and academics to visualise and analyse data for cyber-physical interaction and data-driven applications in civil, construction engineering and management. The facility is a black-box room that offers collaborative and immersive projection on an ultra-high-definition display wall. It is also used to explore three-dimensional design solutions, augmented simulations, and to develop models and algorithms for engineering applications in building design and construction engineering.

This laboratory provides a unique collaborative space with many uses.

It features reconfigurable visualisation, presentation and interaction spaces including a movable/fixed display wall, AI- and VR-capable PCs with attached head-mounted displays, and ample space for free movement in the Extended Reality (VR/AR/MR) environment.

It facilitates collaborative multi-site video conferences, workshops and/or training sessions with shared content on the touchscreen visualisation wall. It also features a range of teaching and research equipment in the area of intelligent construction engineering and management.

There are advanced Virtual and Augmented Reality devices and systems, including mobile VR headsets and state-of-the-art augmented reality headsets. And, a 3D laser scanner and 360-degree camera for capturing images, videos, and data points from any surface with low-ranging error for the study of as-built modelling of existing buildings and infrastructure.

The laboratory subscribes to advanced software packages for 2D/3D modelling and digital twin applications to support educational and research purposes in the visualisation of design and construction engineering applications.

This laboratory features advanced benchtop geotechnical testing apparatus that are used to investigate the engineering behaviour of geomaterials under multi-coupled physics process in energy geotechnology, geoenvironmental and ground improvement applications.

Equipment includes soil classification (sieve, hydrometer, Atterberg limit), soil compaction and California bearing ratio testing, advanced chemo-thermo-mechanical triaxial cells, conventional and highly accurate consolidometers with a settlement accuracy of 1 um, large oedometer for prefabricated vertical drain consolidation testing, modified direct shear apparatus for shear creep monitoring, modified ring shear for advanced soil interface testing, different soil suction measurement and control devices (WP4C, psychrometer, pressure plate), soil electrical resistivity and thermal conductivity device, pundit PL-200 ultrasound testing equipment, surface roughness tester (MarSurf M400), mercury intrusion porosimetry, freeze dryer unit for sampling preparation benchtop centrifuge with in-house built hydraulic conductivity cell, and LaVision particle image velocimetry high-speed cameras (StrainMaster).

This laboratory features a range of teaching equipment for the delivery of courses in hydraulics/water resources engineering.

There is equipment for demonstrating Bernoulli's theorem, the function and dynamics of weirs, pressure and flow measurement, pipe friction and energy loss. The five-metre-long hydraulic flume for demonstrating the mechanics of flow also enables the practical teaching and demonstration of critical and sub-critical flow, hydraulic jump and dune formation. The inductively-coupled plasma mass spectroscopy machine detects metals and several non-metals in liquid samples at very low concentrations. The laboratory also enables jar testing, a procedure that simulates coagulation/flocculation with differing chemical doses to estimate the minimum coagulant dose required to achieve certain water quality goals.

This laboratory features strong corner walls consisting of a one-metre-thick strong floor and three-metre-tall, one-metre-thick ‘L’ shaped reaction walls. The area of the strong floor is five metres by three metres and can carry up to one MN load. The laboratory features a concrete mixing facility for fabricating the real scale structural members. The 100 kN universal testing machine can be used for generating the stress-strain responses of structural steel and aluminium. The light frame structures are used for assessing the fundamental behaviour of beams under different loading conditions. The compressive strength of concrete is obtained by using the concrete cylinder testing machine. TechnoLab’s Experimental Mechanics Teaching System is also a part of the laboratory, providing a hands-on learning experience for undergraduate civil engineering students. It includes experiment kits for measuring reaction forces and deflection in beams and trusses.

Equipment includes strong corner walls, a 100 kN universal testing machine, light frame structures, a concrete cylinder testing machine and TechnoLab structural analysis equipment.

Electronics engineering

Electronics are essential for the modern world, bringing us everything from smart phones and laptops, to electric vehicles and satellite navigation. Our electronic engineering laboratories facilitate design, fabrication and analysis of electronic devices with applications as diverse as robotics and machine vision, to environmental radar and Internet of Things.

This laboratory facilitates image and video processing to tackle applications such as under water video processing based on deep learning models. Another focus is the development of efficient and effective algorithms for real time signal processing in low cost and low power embedded processors. This laboratory has helped researchers to develop edge-aware filtering for graphics and computer vision, an embedded system for real time personal protection equipment recognition and driver fatigue alerts, and real time high definition video enhancement.

Equipment includes high-performance personal computers with powerful graphics processing units and a range of embedded processors such as the Intel Neural Compute Stick, Nvidia Jetson Nano and Xavier AGX, Xilinx and Intel field-programmable gate array development boards.

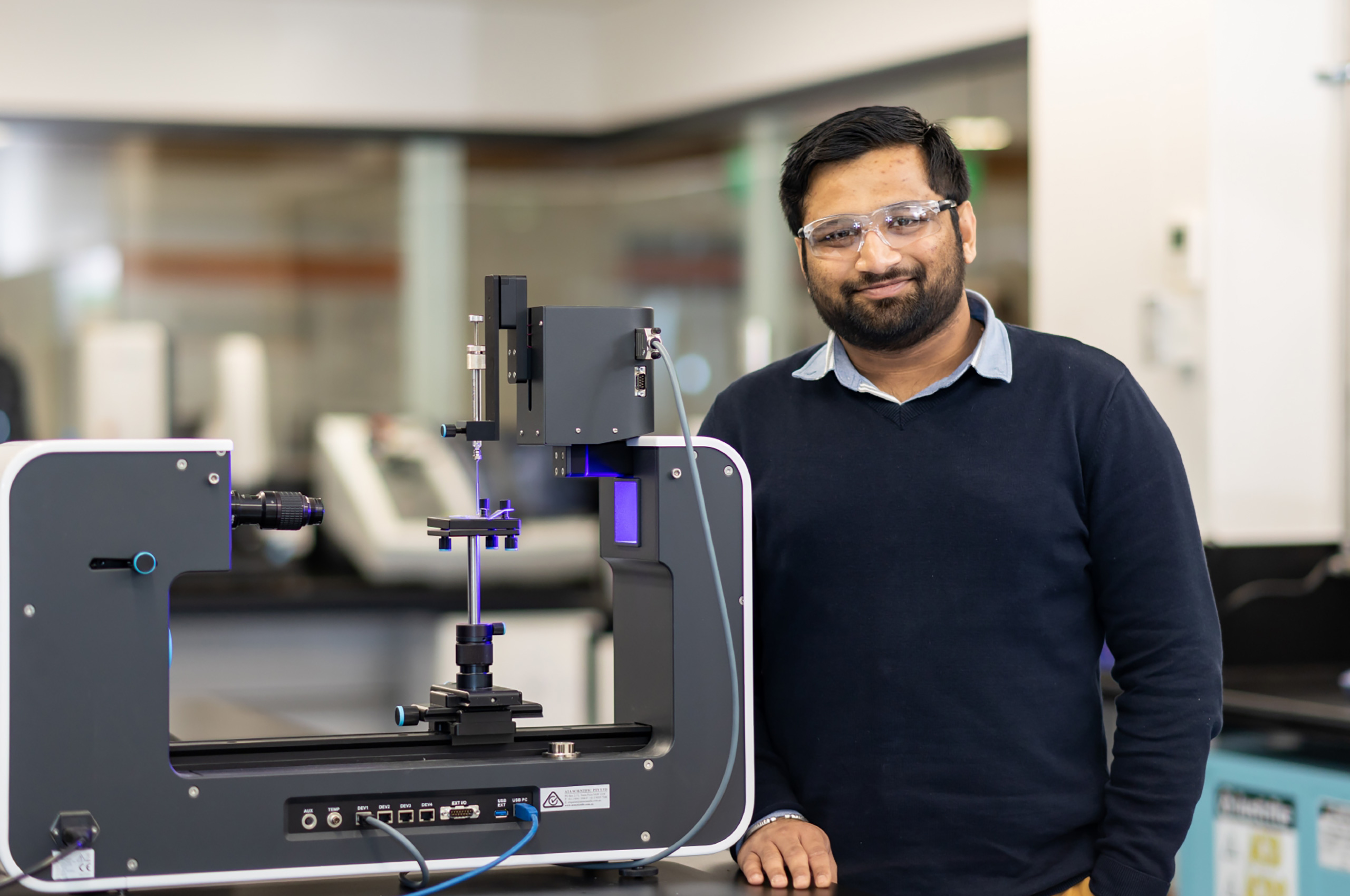

This laboratory facilitates the design, building and testing of functional prototypes in robotics, automation, mechatronic design, machine vision and sensor systems. It helps researchers to solve problems with industry. It has led to the development of sewer condition assessment robots, agricultural pruning robots, radio frequency identification, wildlife Internet of Things tracker and WomBot, a robot designed to explore wombat burrows.

Equipment includes mechanical (3D printing, abrasive waterjet cutting, lasercutting and CNC milling) and electronic (embedded, PCB fabrication and reflow) prototyping capabilities.