Researchers from La Trobe University have developed an innovative recycling solution for synthetic bale twine, helping address the growing problem of agricultural waste.

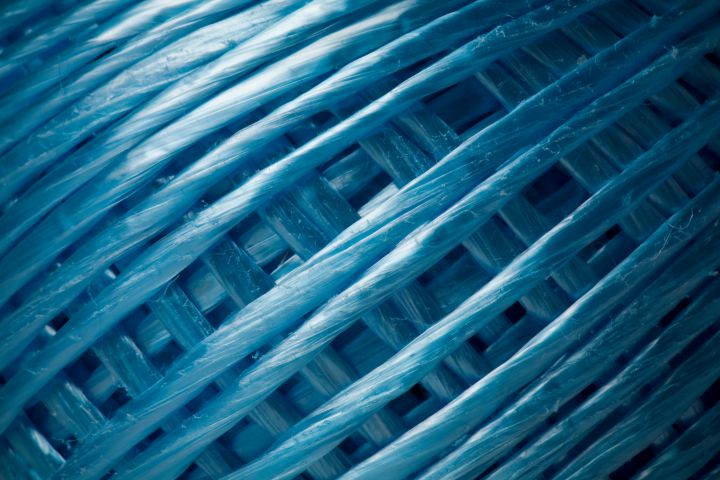

Bale twine is used to bale hay, straw and other crops. It keeps bales compact during transportation and storage.

The global agricultural industry uses millions of kilometres of bale twine annually. It's strong, but it is made from plastic and is not biodegradable. And, recycling it has been a challenge for several reasons including contamination from soil, animal skin or faeces.

Now, La Trobe researchers, in partnership with Ritchie Technology Pty Ltd, are working on a recycling solution.

The project – supported by Sustainability Victoria’s Circular Economy Markets Fund: Materials – has developed a closed-loop recycling system by converting waste plastic into valuable products using an affordable melting machine developed by Ritchie Technology.

“We were able to successfully demonstrate that bale twine can be efficiently melted and reformed into valuable products such as durable garden planters, outdoor furniture and construction materials,” says lead researcher, Associate Professor Ing Kong.

The team say these outcomes showcase the potential applications for recycled materials such as bale twine.

“Not only does it mean that we can help reduce agricultural waste, but we are also promoting sustainability and supporting the circular economy. And, beyond its direct environmental benefits, this work also has the potential to influence industrial practices by providing an example of scalable, low-cost recycling solutions,” Associate Professor Kong says.

The team hope to scale up their initiative for a broad range of applications that could be adapted for other plastic waste streams, ensuring long-term environmental and economic benefits.